Lab grown diamonds represent a significant advancement in both technology and ethical sourcing within the gemstone industry. Utilizing methodologies such as High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD), these diamonds are engineered to replicate the natural processes that occur deep within the Earth.

While the technical aspects may seem straightforward, the implications of these methods on quality, environmental impact, and market dynamics warrant closer scrutiny. Understanding the intricacies of diamond synthesis not only sheds light on their creation but also raises important questions about their place in contemporary society.

Overview of Lab Grown Diamonds

Although natural diamonds have long been celebrated for their beauty and rarity, lab grown diamonds have emerged as a compelling alternative that offers similar aesthetic qualities at a fraction of the environmental and ethical costs. These diamonds are created using advanced technological processes that replicate the natural conditions under which real diamonds form, resulting in stones that possess the same chemical properties, physical properties, and optical characteristics as their mined counterparts.

The unique properties of lab-grown diamonds, such as their clarity, color, and cut, make them highly desirable to consumers. Unlike cubic zirconia, which is a diamond simulant and lacks the structure of real diamonds, lab-grown diamonds are chemically and physically identical to their natural counterparts.

As awareness of the ethical implications of diamond mining grows, market demand for lab-grown alternatives is on the rise. Consumers are increasingly drawn to these diamonds not only for their affordability but also for their sustainability. Lab diamonds are produced without the environmental degradation associated with traditional mining practices, and they are often free from the socio-economic issues related to conflict diamonds.

As a result, they represent a responsible choice for conscientious buyers. This shift in consumer preferences is reshaping the diamond market, positioning lab-grown diamonds as a viable and attractive option for those seeking elegance without compromise.

The Science Behind Diamond Formation

Understanding the science behind diamond formation is essential to appreciating the innovation of lab made diamonds. Diamonds are carbon allotropes that exhibit unique properties resulting from their distinct crystal structure. In nature, diamonds form under extreme conditions of temperature and pressure deep within the Earth’s mantle, where carbon atoms bond in a tetrahedral arrangement. This arrangement not only imparts the characteristic hardness associated with diamonds but also contributes to their remarkable optical properties, such as brilliance and dispersion.

Lab grown diamonds replicate this natural process in a controlled environment, ensuring that the resulting stones possess the same diamond properties as their mined counterparts. By mimicking the high-pressure, high-temperature conditions or employing chemical vapor deposition, manufacturers can create diamonds with identical crystal structures. These methods allow for the precise control of growth conditions, resulting in diamonds that are chemically, physically, and optically indistinguishable from natural diamonds.

A profound understanding of diamond formation science not only enhances the quality of lab grown diamonds but also promotes their sustainable production, positioning them as a responsible choice in the modern gemstone market.

Two Main Production Methods

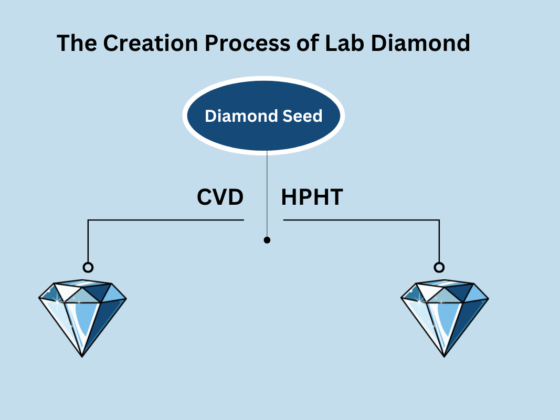

Lab grown diamonds are produced primarily through two recognized methods: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Each of these production techniques has its unique advantages and applications, influencing the evolving landscape of the diamond market.

Both methods contribute significantly to the growing demand for cultured diamonds, which are increasingly favored for their ethical and environmental advantages. As market trends continue to shift towards sustainable practices, understanding these production techniques is essential for consumers and industry stakeholders alike, as they navigate the complexities of the diamond market.

High Pressure High Temperature (HPHT)

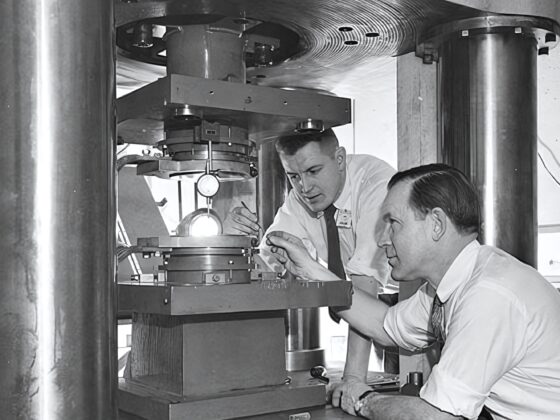

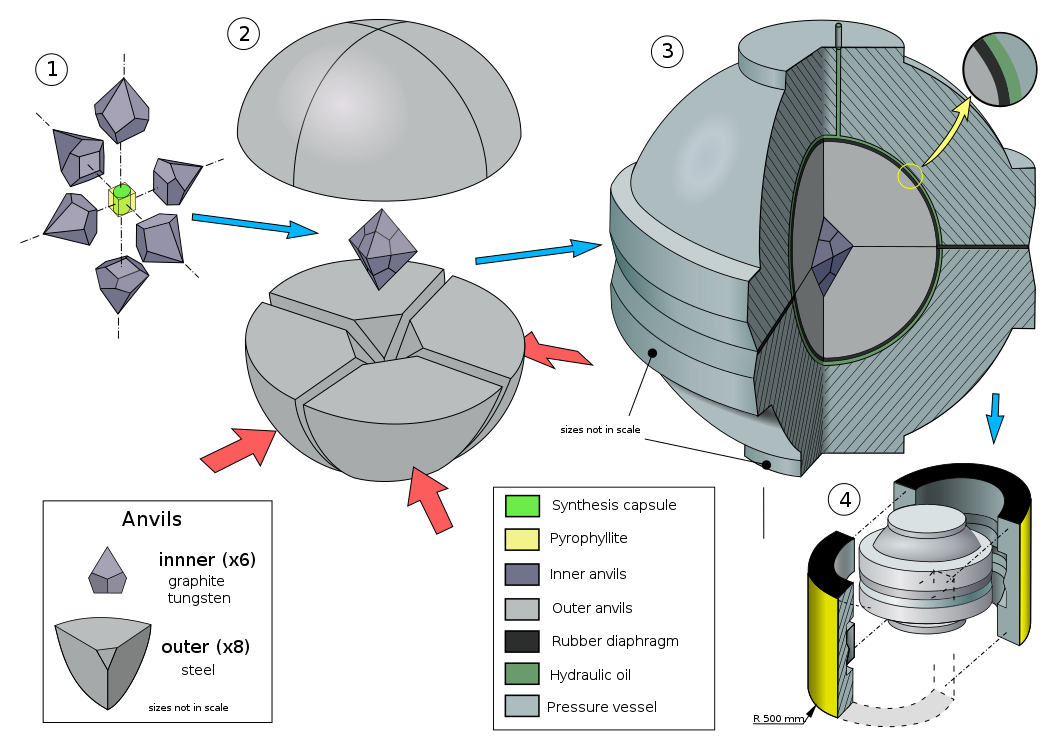

At the core of Lab-Grown Diamond Production Methods, the High Pressure High Temperature (HPHT) process replicates the unusual conditions found deep within the Earth’s mantle, where natural diamonds form. This innovative technique facilitates the transformation of carbon into diamonds by subjecting it to extreme pressures exceeding 1.5 million pounds per square inch and temperatures of around 1,500 degrees Celsius.

The process begins with a diamond seed, a small fragment of diamond placed in a chamber filled with pure carbon. Under these conditions, the carbon melts and crystallizes around the seed, forming a rough diamond. The HPHT method produces synthetic diamonds that are chemically, physically, and optically identical to natural diamonds.

These diamonds can be crafted into colorless diamonds or intentionally infused with impurities to create colored varieties. The controlled environment allows for precise manipulation of the diamond’s growth, resulting in high-quality gems with fewer inclusions.

Additionally, HPHT is instrumental in creating larger diamonds, as the process can be extended to grow substantial crystals. One of the significant advantages of HPHT is its ability to enhance or alter the color of lower-grade diamonds permanently.

For example, nitrogen impurities can produce yellow hues, while nitrogen-free environments yield colorless stones. This makes HPHT diamonds not only suitable for fine jewelry but also for industrial applications like cutting tools due to their unmatched hardness.

Chemical Vapor Deposition (CVD)

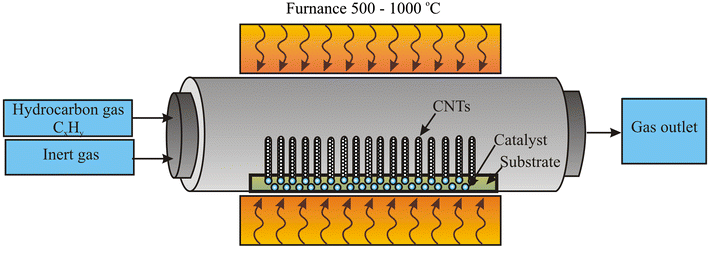

Building on HPHT advancements, Chemical Vapor Deposition (CVD) offers another method for creating lab-grown diamonds under different conditions. In this process, a thin diamond seed is placed in a vacuum chamber, which is heated to around 800°C and flooded with a hydrocarbon gas mixture, such as methane and hydrogen. The gas is ionized into plasma, breaking its molecular bonds and allowing pure carbon atoms to deposit onto the seed layer by layer.

Over weeks, this process forms a fully developed rough diamond. CVD technology excels in producing high-purity diamonds with fewer inclusions compared to other methods. These diamonds are widely used in industrial applications due to their superior thermal conductivity and hardness.

Additionally, CVD enables customization, allowing for tailored sizes and fancy colors, further expanding its applications in both jewelry and industry. While both HPHT and CVD produce real diamonds, indistinguishable from natural ones without specialized equipment, they differ in their approach.

HPHT mimics Earth’s natural processes more closely but requires higher energy input, whereas CVD operates at lower temperatures and pressures, making it more energy-efficient.

The Role of Carbon Sources

While the process of diamond synthesis is intricate, the choice of carbon sources plays a crucial role in determining the quality and characteristics of the resulting diamonds. Carbon sourcing is fundamental in both the CVD and HPHT methods. The purity and composition of the carbon feedstock directly influence the clarity, color, and overall quality of the diamonds produced.

In recent years, the diamond industry has increasingly prioritized sustainable practices in carbon sourcing. Many manufacturers are now opting for recycled carbon materials, such as graphite, to minimize environmental impact and reduce reliance on finite natural resources. This shift not only enhances the sustainability of man-made diamonds but also aligns with consumer demand for ethically sourced products.

Moreover, innovative approaches, such as using carbon derived from renewable sources, are being explored. By integrating these sustainable practices into carbon sourcing, the lab-grown diamond industry can further distinguish itself from traditional mining operations, offering a more eco-friendly alternative while maintaining high-quality standards. Ultimately, the careful selection of carbon sources is essential for producing diamonds that meet both aesthetic and ethical expectations in today’s market.

Growth Process and Timeframe

The growth process of man made diamonds is a meticulously controlled procedure that typically spans several weeks, depending on the method utilized.

Throughout the process, sustainability practices are integral, as they aim to minimize environmental impact compared to traditional diamond mining. The use of renewable energy and efficient resource management further enhances the ecological footprint of lab-grown diamonds, appealing to a growing consumer base that values ethical sourcing.

Consumer perceptions of man made diamonds are increasingly positive, as many individuals recognize their environmental advantages and ethical implications. The transparency in production processes fosters trust, contributing to the growing acceptance of these diamonds in the market. As awareness increases, the demand for lab-grown diamonds continues to rise, signaling a shift towards a more sustainable and ethically responsible approach to luxury goods.

Quality Control in Production

Quality assurance is a fundamental aspect of man made diamond production, ensuring that each stone meets stringent industry standards. The process begins with rigorous monitoring during the growth phase, where parameters such as temperature, pressure, and chemical composition are meticulously controlled. This attention to detail is crucial for achieving the desired diamond crystal structure and optical properties.

After the diamonds are grown, they undergo a series of inspections to assess their clarity, color, and cut. Advanced imaging technology is employed to detect any internal inclusions or irregularities, which could affect the diamond’s overall quality. Each stone is then graded according to established production standards, allowing for consistency and reliability in the final product.

To further uphold quality assurance, lab-made diamonds are often subjected to third-party certification. This process provides an unbiased evaluation of the diamonds, ensuring that they meet not only aesthetic requirements but also ethical and environmental considerations. By adhering to these rigorous quality control measures, producers can confidently offer laboratory-grown diamonds that rival their natural counterparts in both beauty and integrity.

FAQs

Are Lab Grown Diamonds More Affordable Than Natural Diamonds?

Lab-grown diamonds typically exhibit a more favorable price comparison compared to natural diamonds, primarily due to reduced production costs and evolving market trends. This affordability enhances consumer accessibility while maintaining similar aesthetic and structural qualities.

Can Lab Grown Diamonds Be Used in Engagement Rings?

Lab-grown diamonds are an excellent choice for engagement ring styles, offering the same aesthetic appeal and diamond durability as natural diamonds. They provide a sustainable, ethical alternative without compromising on quality or beauty.

Do Lab Grown Diamonds Have Resale Value?

Lab grown diamonds possess a variable resale value, largely influenced by consumer perception. While some buyers appreciate their ethical origin, others may prioritize traditional diamonds, affecting the overall dynamics of the resale market significantly.

Are Lab Grown Diamonds Indistinguishable From Natural Diamonds?

Lab grown diamonds are often indistinguishable from natural diamonds to the naked eye; however, composition differences exist at a molecular level. Market perceptions vary, influencing consumer preferences and resale values between the two types of diamonds.

What Certifications Do Lab Grown Diamonds Have?

Lab grown diamonds typically possess certifications from reputable gemological institutes, ensuring adherence to established grading standards. Common certification types include those from the Gemological Institute of America (GIA) and the International Gemological Institute (IGI), ensuring quality and authenticity.